Großhandel koreanische Make -up -Kosmetik -Magnetschwebmodul Display Ständer

Beschreibung

Großhandel koreanische Make -up -Kosmetik -Magnetschwebmodul Display Ständer

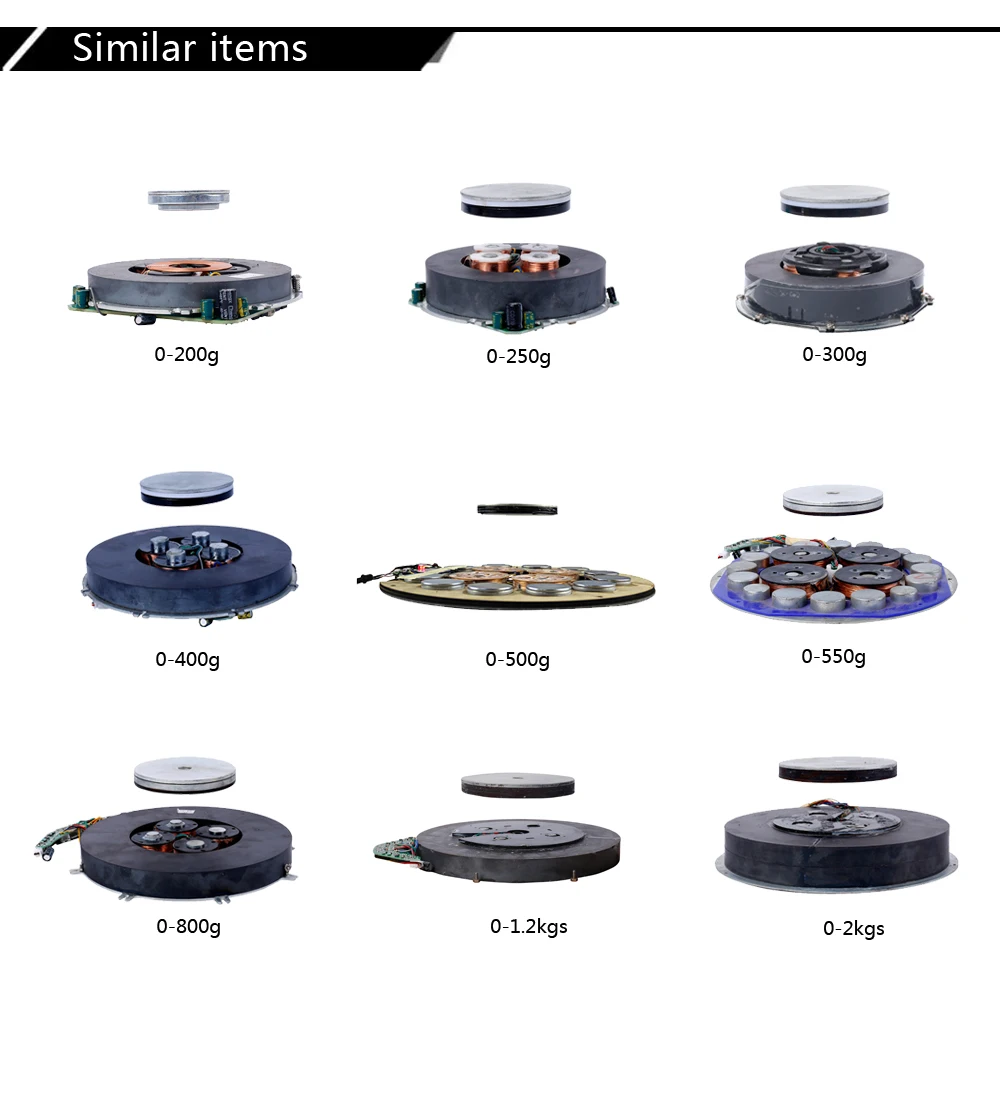

| Besonderheit | Magnetische Levitationstechnologie |

| Gewichtsdauer | 0-400G |

| Levitationslücke | 20-25mm |

| DC -Adapter | 15V 1A |

| Stromspannung | 100-240V |

| Mindestbestellmenge | 1PC |

| Packliste |

1pc/pearl cotton foam+brown bull carton Kartongröße: 30x30x25cm G.W.: 5Kgs |

Company Information:

Goodwell wurde in gegründet in 1999 in Shenzhen City, China von MR. Robert Wang, Ein Elektronikingenieur und besitzt ein Fabrikland in Zhaoqing City und Covers 27,000 square meters in 2015. Goodwell is the first manufacturer to apply electromagnetic levitation technology to craft products, Geschenke, Spielzeug und Werbeanzeigen und Massenproduktion hier in China, and has been being the leading specialist in the manufacture of “elektromagnetische schwebende Systeme “für 19 years.Goodwell is the inventor of bottom levitation systems and patented them in china and USA. And all the produts are compliant with EMC, LVD, ROHS and FCC certificates. Goodwell is working with french designer and has a branch office in Paris.insisting on that qualities and techniques are the most important things, Goodwell is the most professinal team for ODM/OEM designs with different magnetic levitation devices.

We have been developing,designing and massive producing magnetic levitation products based on our patented levitation technology since 1999. Our products can be divided into three categories; levitation modules, display products and design crafts. All of our products are designed and produced in zhaoqing city, china.

HISTORYIn 1999, Herr. Li Liangqing and Mr. Robert Wang had the idea of combining their creative expertise on toolings and mechatronics respectively to execute a small workshop in shenzhen and produce mini magnetic floating globes.. They developed a kind of top levitation technology and began to massive producing the mini top floating globe and export to USA, which the globe is hanging in the mid air from the top. Herr. Li and Mr. Robert had many brainstorm sessions on applications for this technology, and they decided to work with french scientists and designers for the electromagnetic levitation in the year of 2006. Together they all decided that bottom mangetic levitation is the most promising one and got china and US invention patents for the bottom magnetic levitation technologis. In November 2006, Herr. Li and Mr.Robert bought a 27000 square meter factory lands. In 2015, Goodwell is registered officially in Zhaoqing city and has a branch office in Paris for new designs and marketing.Since then the product catalogue has been expanded with levitation modules, Produkte anzeigen, Kunsthandwerk, Geschenke und verschiedene ODM/OEM -Innovationen und Kreationen.

LOCATIONS:Chinese factory is located in No.1, Heping Road, Shali Industrial Park, Dawang High Technology Development Zone, Stadt Zhaoqing, 526238

French branch office is located in 10 rue Jean cottin- 75018 Paris FranceWe’re all inspiring one another by our combined goal to create.

CONTACTGoodwell ElectronicsNo.1, Heping Road Shali Industrial Park Dawang High Technology Development Zone, Zhaoqing city, 526238, Provinz Guangdong, China.Tel.: +86 758 3626208

Branch office in France: MagneticLand10 rue Jean cottin- 75018 Paris FranceTel.: +33 1 40 340222

Ist Ihr Unternehmen eine Fabrik??Ja,Wir sind der professionellste Hersteller für die Herstellung von Magnetschwebeprodukten 20 Jahre.

Ist Ihr Unternehmen eine Fabrik??Ja,Wir sind der professionellste Hersteller für die Herstellung von Magnetschwebeprodukten 20 Jahre.

Wie wäre es mit der Produktionskapazität Ihrer Fabrik in einem Monat??Monatliche Kapazität:15000 Sätze/Monat.

Wie viele MOQ(Mindestbestellmenge) ist in Ihrer Fabrik?Mindestbestellmenge :1Stück/Stück

Kann ich verschiedene Designs mischen??

Sicher!

Haben Sie andere ausländische Kooperationen??

Ja, Unsere Hauptmärkte sind die USA, Europa und Japan.

Kann ich einen günstigeren Preis erhalten, wenn ich große Mengen bestelle??

Ja, günstigere Preise bei größeren Bestellungen.

Wenn Sie meine Bestellung versenden?

Vorlaufzeit der Probe: 5-7 Tage nach Erhalt der Probe

Lieferzeit für Massenbestellungen: 30-45 Tage danach 30% Einzahlungsbeleg,

Es kann jedoch auf der Grundlage der Bestellmenge, des Produktionsplans und der Produktionsvereinbarungen ausgehandelt werden.

Wie wäre es mit der Zeit des Qualitätsstipendiaten??

Ein Jahr!

Wie können Sie die Produktionsqualität garantieren??

Our production quality follow EMC, LVD and ROHS standard.

Wir verfügen über 20 Jahre Erfahrung als QC-Team mit einem strengen und professionellen Qualitätskontrollsystem. Wir haben 4 Mal Inspektion für jedes fertige Produkt vor dem Verpacken.

Dritte Teilprüfung akzeptabel.

So tätigen Sie die Zahlung ?

Wir akzeptieren Zahlungen per T/T oder West Union und PayPal

welcher Port für die Lieferung ausgewählt werden kann ?

Shenzhen.

Welche Arten der internationalen Expresszustellung sind verfügbar??

Wir haben Vorzugsvertragstarife mit DHL, TNT und Fedex, und können Ihnen einen guten Frachtservice mit niedrigen Frachtkosten bieten.

Ist die Zahlung für mich sicher, da wir die erste Zusammenarbeit sind??Wir können die Handelsversicherung auf Alibaba durchführen, Dies garantiert den Erhalt Ihrer Produkte.

Können Sie eine Probe für mich machen??

Ja, Wir können Ihnen ein Muster zur Genehmigung anfertigen, aber es gibt eine Probegebühr, die nach Erreichen einer bestimmten Menge zurückgegeben wird.

Übernehmen Sie meine Einfuhrsteuer??NEIN, das werden wir nicht.

Können Sie das Logo auf die Produkte drucken??Ja, Es ist möglich, Logos auf unsere Produkte zu drucken. Die Vorlage des Logodrucks im AI- oder PDF-Format ist erforderlich, sobald die Musterbestellung aufgegeben wurde.

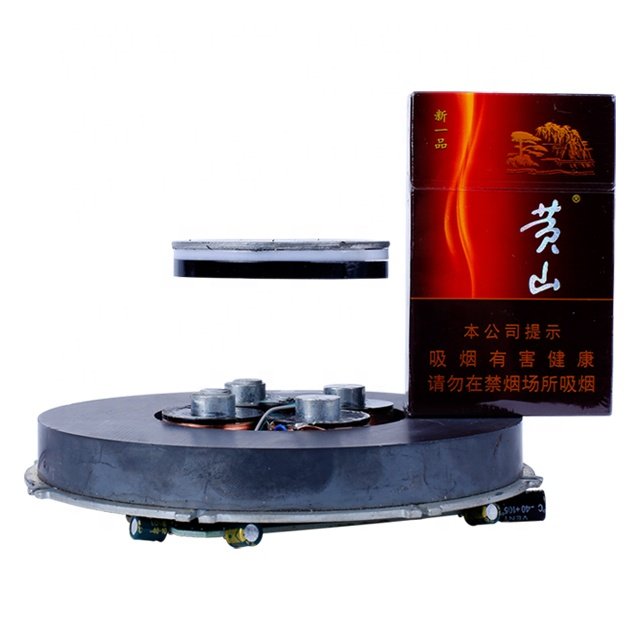

Magnetic levitation system is widely used in the areas such as high-speed motion and precision engineering industry. In reality, Eine stabile Levitation mit einem Maximum von 80 mm Luftspalt wurde erreicht, und das schwebende ferromagnetische Objekt kann eine 2 kg -Belastung in Maximum tragen, die auch erreicht wurde. Wir haben diese bereits im Handel angewendet, and the technology is also helpful to develop new kinds of levitation system for industries.

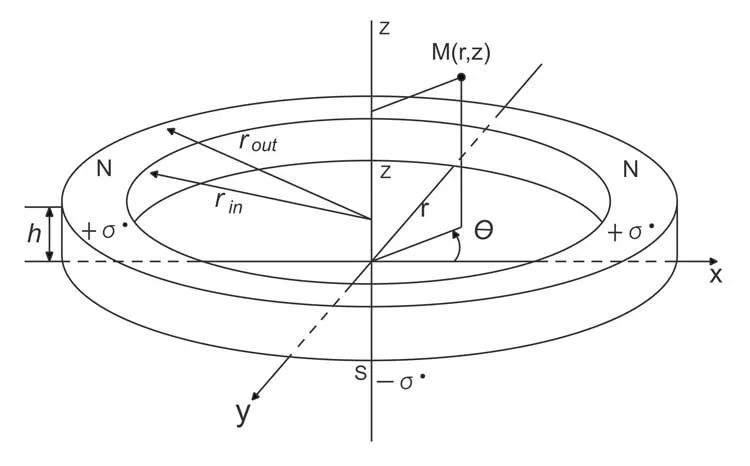

This magnetic levitation technology is a control method using a ring magnet for the stable levitation of a cylindrical ferromagnetic object. Die Levitation hat eine starke Stabilität mit Anti-Disturbanz-Fähigkeiten, und Gewicht kann auf den schwimmenden Magneten platziert werden. Das vom Ringmagnet erzeugte Magnetfeld bietet Stabilitäten in 3 Grad der Freiheit des schwimmenden Magneten, and a feedback control in the horizontal plane is introduced to the control system. The stable magnetic levitation refers that the floating object is static or is with a controllable rotation motion along one axis. Die Antigravitationskraft für die stabile Levitation wird von der Basis unter dem schwimmenden Objekt bereitgestellt. Nach analytischer Berechnung und Experimenten, Die durch axial magnetisierten Permanentmagnet-Ringe erzeugten Magnetfelder haben spezielle Eigenschaften. Entlang der symmetrischen Achse, Die Richtung des Magnetfeldes variiert an zwei bestimmten Punkten. Diese interessante Eigenschaft bietet Stabilitäten des Suspending -Magneten.

Die Einrichtung des Levitationsgeräts wird in der Zeichnung angezeigt. Ein axial magnetisierter Permanentmagnetring, dessen Nordpol auf der Oberseite auf der Basis des Setups liegt. Drei Hallsensoren werden zum Nachweis der momentanen Koordinaten des schwimmenden Magneten an drei Achsen verwendet. Die horizontale Position des schwimmenden Magneten wird durch zwei Gruppen von Spulen gesteuert. Der Nordpol des schwebenden Magneten befindet sich ebenfalls auf der Oberfläche, was nicht mit dem gesunden Menschenverstand übereinstimmt, das sich im Gegensatz zu Polen gegenseitig anziehen, sich gegenseitig nicht abwehren, um den schwimmenden Magneten Anigravitätskraft zu gewährleisten, which is the key point for this technology.

It is worth mentioning that the hall component for z axis acts just for a circuit protection. If the floating magnet is within the certain controllable area, there is no need to control its position along z axis.

Intuitively speaking, the magnetic field lines proceed from the north pole of a permanent magnet to the south pole. For an axially magnetized permanent-magnet ring, the magnetic field lines have two ways to travel. One is through the external space surrounding the magnetic ring, while the other way is through the internal space of the ring. Along the axis of symmetry, two points at which the magnetic field varies its direction exist.

Der schwimmende Magnete kann sein Gleichgewicht innerhalb eines bestimmten Bereichs entlang der Zachse finden, und die Höhe des Luftspalts kann sich während der Levitation ändern (Wenn etwas Gewicht angelegt oder aus dem schwimmenden Magneten weggenommen wird). Vorausgesetzt, die Größe der schwimmenden magnetischen Palette bleibt unverändert, Es besteht eine entsprechende Beziehung zwischen der Höhe des Luftspalts und dem Wert der vom Ringmagneten bereitgestellten Angravitätskraft, das in Fig. 1 dargestellt wurde. unten. Wenn sich das Gewicht des schwebenden Objekts ändert (Z.B., Wenn ein Holzblock auf den schwimmenden Magneten platziert wird), Das schwimmende Objekt wird sein Gleichgewicht an einer neuen Position finden. If the floating magnetic pallet jumps up because of some distur-bance, the direction of the resultant force acts on the magnet may be downward. This property significantly reduces the overshoot of the balance along z axis. Which means the load on the magnet pallets varies, and the air gap will be varied to reach the balance.

The movement of the floating magnet along x axis and y axis in the horizontal plane are controlled by the feedback system. Zwei Gruppen von Spulen werden verwendet, um den schwimmenden Magneten in der Mitte des Magnetfelds zu fangen, der durch den Ringmagneten erzeugt wird. Die Rückkopplungsregelung wird entlang der beiden Abmessungen getrennt implementiert. Hall -Komponenten, die in der Lage sind, das vom schwimmende Magnet erzeugte Magnetfeld zu erkennen und in Spannungssignale zu übertragen, spielen die Rolle von Sensoren. Um die Wirkung des Magnetfelds zu beseitigen, das durch den Ringmagneten und die Spulen erzeugt werden, Die beiden Spulen befinden sich symmetrisch entlang einer Achse und die Hall -Komponente befindet sich in der Mitte des Ringmagneten und zwei Spulen, das in Fig. 1 dargestellt ist. unten. Currents with the same intensity but reversed direction are added into each coil so that the magnetic field created by them make a cancelation at the center.

Under the circumstance of the stable levitation, a reference voltage is selected. Within a small range, Eine lineare Beziehung wird zwischen der Differenz von der Eingangsspannung der Hall -Komponente zur Referenzspannung und der Abweichung des schwimmenden Magneten vom Gleichgewichtspunkt gehalten, wobei der Differenzwert Null ist. Daher, Einfache negative Feedback kann die stabile Kontrolle erreichen. Außerdem, wegen Fehlern und Störungen. Einige besondere Mechanismen werden eingeführt, wie z. B. eine schwimmende Referenzspannung. Es wird gezeigt, dass die Levitation des zylindrischen ferromagnetischen Objekts stabil ist. Es hat eine Anti-Overturn-Fähigkeit und eine Anti-Disturbanz-Fähigkeit. Die Anforderungen für die Levitation sind überhaupt nicht hart, und das Gerät kann sogar auf eine schiefe Plattform gestellt werden.

Rezensionen

Es liegen noch keine Bewertungen vor.