How Electromagnetic Levitation Modules Work and Where They Are Used

You see an electromagnetic levitation module at work when a train floats above its track or a product hovers in a display case. The module uses alternating electromagnetic fields to lift objects and keep them stable, fighting gravity without physical contact. Imagine holding a magnet above another magnet and watching it float—that simple idea powers maglev trains, magnetic bearings in motors, and eye-catching product displays.

Market Segment | 2024 Market Size (USD Billion) | Forecast Year | Projected Market Size (USD Billion) | CAGR (%) |

|---|---|---|---|---|

Magnetic Levitation System Market | 2033 | 7.2 | 8.5 | |

Magnetic Levitation Rotation System Market | 2030 | 3.27 | 9.6 |

Key Takeaways

Electromagnetic levitation modules lift objects without touching them by balancing magnetic force against gravity, making objects float steadily in mid-air.

These modules use electromagnets, sensors, and control systems working together to adjust magnetic fields quickly and keep objects stable and balanced.

Applications include maglev trains that float above tracks for fast, smooth travel; magnetic bearings that reduce friction in machines; and precise motion control in scientific instruments.

Electromagnetic levitation also enables contactless melting of metals for cleaner materials and creates eye-catching floating product displays that attract attention.

The technology is growing fast with new uses in healthcare, microbotics, and 3D bioprinting, offering energy savings and longer equipment life despite challenges like cost and control complexity.

Principle of Electromagnetic Levitation

Electromagnetic Levitation Module Basics

You can think of an electromagnetic levitation module as a system that lets you lift objects without touching them. The main idea is to create an upward force that matches the pull of gravity. When you use this module, you see an object float in mid-air because the magnetic force pushes up just as hard as gravity pulls down. This balance keeps the object from falling or rising.

The module uses electromagnets, which are coils of wire that carry electric current. When you turn on the current, the coils create a magnetic field. By changing the strength and direction of this current, you control the magnetic field and the force it produces. This lets you adjust how high or low the object floats.

Note: For stable levitation, the system must react quickly. If the object moves even a little, the module senses the change and adjusts the magnetic field to bring the object back to its original spot. This active control is what keeps the object steady and prevents it from flipping or sliding away.

Magnetic Fields and Suspension

Magnetic fields are invisible forces that can push or pull on certain materials. In an electromagnetic levitation module, you use these fields to suspend objects in the air. The module often creates alternating electromagnetic fields, which means the direction and strength of the field change rapidly. This change can induce electric currents, called eddy currents, in nearby metal objects.

These eddy currents make their own magnetic fields. The new fields push against the original field from the module. This push creates a repulsive force, which lifts the object and keeps it floating. You can see this effect in maglev trains, where the train floats above the track with no wheels touching the ground.

Here’s a simple breakdown of how alternating magnetic fields create lift:

The module generates a changing magnetic field using electromagnets.

This field induces eddy currents in a nearby metal object.

The eddy currents create their own magnetic field that pushes back against the module’s field.

The repulsive force lifts the object, letting it float.

Sensors and feedback systems keep the object stable by adjusting the field as needed.

You can also find superconducting levitation, where special materials called superconductors interact with magnetic fields to create stable lift. In this case, the superconductor locks magnetic lines in place, holding the object steady without friction.

When you use an electromagnetic levitation module, you harness the power of magnetic fields and precise control to make objects float. This technology lets you explore new ways to move, display, and handle objects without touching them.

Components and Mechanisms

Electromagnets

You find electromagnets at the heart of every electromagnetic levitation module. These coils of copper wire create strong magnetic fields when you run electric current through them. In levitation modules, the electromagnets switch on and off very quickly—sometimes up to 100,000 times per second. This rapid switching lets you keep objects floating and stable. Unlike regular electromagnets that stay on or off, these respond instantly to changes in the position or tilt of the floating object. You often see steel cores inside the coils. These cores become temporary magnets when a permanent magnet comes close, which boosts the magnetic field and helps with levitation.

Tip: The electromagnet coil, transistor, diode, resistors, and power supply all work together. The transistor acts as a switch, the diode protects the circuit, and the resistors control the current. You need each part to keep the system safe and working smoothly.

Main components in a typical module:

Electromagnet coil

Hall sensor (A3144)

Transistor (MOSFET)

Diode

Resistors

Power supply

Sensors and Feedback

Sensors help you detect the exact position and movement of the floating object. Hall effect sensors are common because they measure magnetic fields and give fast feedback. You also find optical grids, encoder sensors, capacitive sensors, inductive sensors, and ultrasonic sensors in different systems. Each type has strengths and weaknesses. For example, optical sensors give high accuracy but need protection from dust. Magnetic sensors work well in noisy environments.

Description / Usage | Advantages / Notes | |

|---|---|---|

Magnetic Sensors (Hall sensors, magnetoresistive arrays) | Used for position detection, including initialization procedures with arrays of Hall sensors. | Robust, low cost, suitable for industrial applications; used for initialization and continuous sensing. |

Optical Incremental Sensor Grids | Placed below movable stages for high precision position detection. | High accuracy but sensitive to environmental conditions (dust, oil); requires sealed mechanism. |

Encoder Sensors (Incremental and Absolute) | Used in gantry and linear maglev systems for detecting multiple degrees of freedom. | High resolution; absolute encoders available but less common; incremental encoders need referencing. |

Capacitive Sensors | Detect position by changes in capacitance due to overlapping plate area changes. | Sensitive to electromagnetic interference and material proximity changes; less robust in noisy environments. |

Inductive Sensors (LVDTs, RVDTs) | Measure linear and rotary displacement via inductance changes caused by metallic objects. | Reliable in harsh industrial environments; limited sensing range; affected by nearby metals. |

Ultrasonic Sensors | Use sound wave propagation to measure distance without contact. | Wide detection range; affected by temperature, wind, and surface conditions; less reliable than magnetic sensors. |

You rely on feedback from these sensors to keep the object stable. The system checks the gap between the object and the electromagnet many times each second. If the object moves, the module adjusts the magnetic field right away.

Control Systems

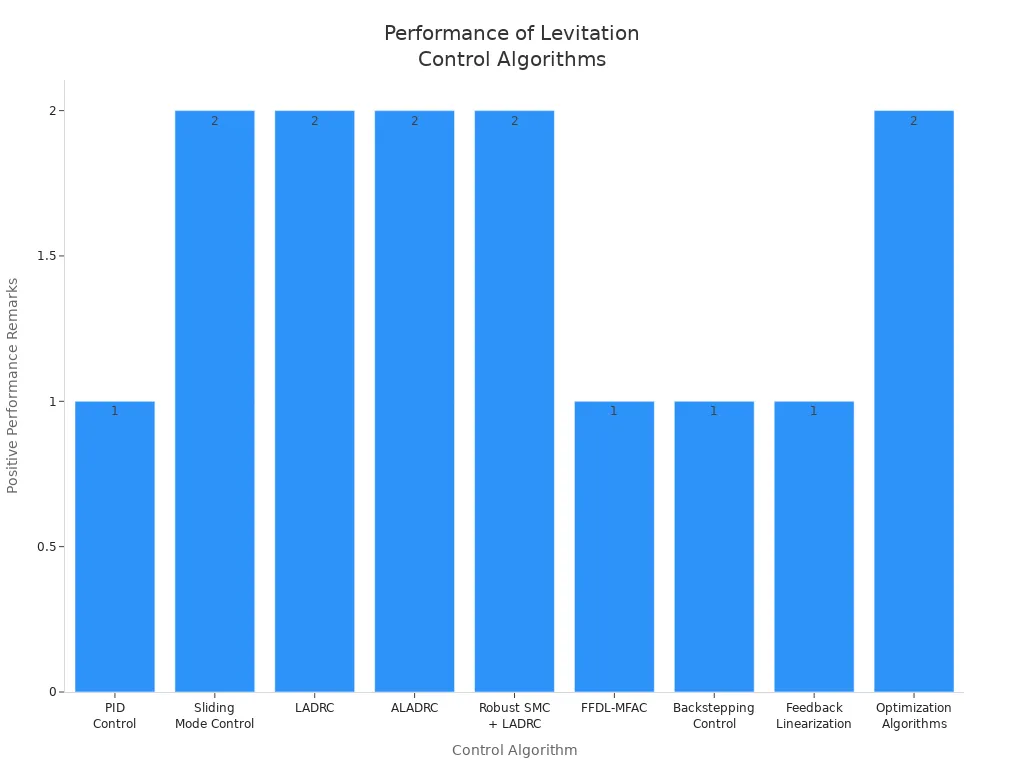

Control systems act like the brain of the electromagnetic levitation module. They use feedback from sensors to decide how much current to send to the electromagnet. You often see advanced algorithms such as PID control, sliding mode control, and adaptive disturbance rejection. These methods help you keep the object floating, even if something tries to disturb it.

Note: Fast and accurate feedback is key. If the control system reacts too slowly, the object can wobble or fall. Modern modules use controllers that adjust the magnetic field in real time, keeping everything balanced.

You see how all these parts—electromagnets, sensors, and control systems—work together. They let you levitate objects safely and smoothly, opening up new possibilities in science, industry, and everyday life.

Operation

Activation and Placement

When you activate an electromagnetic levitation module, you follow a series of steps to get the object floating. First, you assemble the physical components. You attach the electromagnet to the stand and connect the control circuit, which includes an op-amp, MOSFET, and flyback diode. You wire the sensors, such as an IR LED and photoresistor, to detect the object’s position. You mount the potentiometer and toggle switch on the case.

Next, you prepare the levitating object. You make sure the magnets inside have the correct polarity and identical weights. You power on the circuit and check the op-amp output voltage. You adjust the potentiometer reference voltage until the output toggles between high and low as the magnet moves. If the magnet flips or repels, you reverse the wiring polarity of the electromagnet.

You run test code to verify sensor readings and switch states. You calibrate the system by adjusting values in the code based on sensor feedback. You turn on the device, set the switch, and open the serial monitor. You fine-tune the levitation height by adjusting the electromagnet position and loading the code to maintain stable levitation.

Tip: You may need to monitor current draw and adjust the reference voltage to find the levitation window. For wireless power setups, you attach the primary inductor and compensate for added weight.

Stability and Adjustment

Once the object floats, you need to keep it stable. You place a linear Hall probe sensor close to the electromagnet. This sensor enables high-frequency oscillation and effective pulse-width modulation (PWM) control. You stabilize the power supply to prevent voltage fluctuations that could destabilize levitation.

The control circuit switches the electromagnet current on and off rapidly based on the sensed magnetic field. The PWM signal adjusts smoothly with the object’s position, keeping the magnetic force balanced. You analyze stability by modeling the vertical displacements of magnetic poles and the platform’s pitch and tilt angles. Small-angle approximations help you simplify these relations and decouple motions.

You use a PID feedback control loop to actively adjust magnetic forces based on sensor input. Accelerometers detect inclination angles, and the system applies PID control in both X and Y directions. You distribute control outputs among multiple electromagnets to balance the object’s position and orientation. Mechanical design optimizations, such as placing electromagnets closer to the center, increase the inclination angle range and prevent interference.

Note: You must optimize the inductor shape and electrical parameters for energy efficiency. Numerical modeling and physical measurements help you understand and improve the system.

With these steps, you operate an electromagnetic levitation module and maintain stable, contactless suspension.

Applications

Electromagnetic levitation modules have changed how you move, measure, and display objects. You see these modules in many fields, from transportation to science labs and even in stores. They help you achieve frictionless motion, reduce wear, and save energy. Let’s explore where you find these modules and why they matter.

Maglev Trains

You experience the power of electromagnetic levitation modules when you ride a maglev train. These trains float above the tracks, using strong magnetic fields to lift and move at high speeds. You do not feel the bumps of wheels or hear the noise of metal grinding on rails. The train glides smoothly, thanks to the lack of friction.

Maglev trains use two main types of levitation: electromagnetic suspension (EMS) and electrodynamic suspension (EDS). EMS uses active magnets to keep the train close to the track, while EDS uses superconducting magnets for higher speeds. You can see how fast these trains go in the table below:

Maglev Train/System | Levitation Type | Operational Speed (mph) | Levitation Height | Capacity/Additional Notes |

|---|---|---|---|---|

Shanghai Transrapid (China) | Electromagnetic Suspension (EMS) | 270 (commercial) | ~1.3 cm (0.5 inch) | Commercial operation since 2003; uses EMS; wider than conventional railcars, offering more interior space. |

Japan SCMaglev | Electrodynamic Suspension (EDS) | 311 (regular test runs), 374-375 (peak test) | 1–10 cm (0.4–3.9 inches) | Uses superconducting magnets; achieved rail speed records; commercial operation planned post-2027. |

China new urban maglev lines | EMS or other designs (driverless) | ~125 (planned) | N/A | Designed for high-capacity, lower-speed urban transit; driverless operation with computer sensors. |

You notice that maglev trains can reach speeds over 300 mph. They use less energy than airplanes and traditional trains because there is no friction between the train and the track. Only air resistance and electromagnetic drag slow them down. This makes maglev trains a smart choice for fast, energy-efficient travel.

Maglev trains use electromagnetic levitation modules to float and move. You get a smooth, quiet ride and help the planet by saving energy.

Magnetic Bearings

You find magnetic bearings in machines that spin very fast, like turbines, compressors, and medical devices. These bearings use electromagnetic levitation modules to hold spinning parts in place without touching them. You do not need oil or grease, and you avoid the problems of friction and wear.

Magnetic bearings last much longer than regular bearings. They can spin up to 100,000 times per minute without getting hot. You save money on maintenance because there is no need for lubrication or frequent repairs. The system uses sensors and controllers to keep everything balanced and safe. If something goes wrong, the system can shut down before damage happens.

Magnetic bearings help you run machines smoothly, save energy, and reduce downtime. You get longer life and lower costs.

Precision Motion Control

You use electromagnetic levitation modules in scientific instruments that need very precise movement. These modules let you move objects without touching them, so you avoid friction and backlash. You can control position down to the nanometer level, which is one-billionth of a meter.

Maglev planar motors give you six degrees of freedom, so you can move and rotate objects in any direction. You find this technology in semiconductor manufacturing, micromachining, and biomedical devices. The system uses advanced models to control force and torque, making sure you get accurate and repeatable results.

Metric | Typical Value |

|---|---|

Positioning Accuracy |

You can achieve repeatability accuracy down to sub-micrometer levels. This means you can trust your measurements and processes, even for the smallest parts.

With electromagnetic levitation modules, you reach new levels of precision in science and industry.

Contactless Melting

You see electromagnetic levitation modules at work in materials science, especially for melting metals without touching them. The module creates a strong magnetic field that lifts and heats the metal sample. The metal melts while floating in the air or in a vacuum.

This contactless process keeps the metal pure because it never touches a container. You can melt reactive metals like titanium and tungsten without contamination. The system lets you control the position and temperature of the molten metal very accurately. You can also remove unwanted elements, like oxygen, and create new alloys with special properties.

Contactless melting with electromagnetic levitation modules helps you make cleaner, better materials for advanced technology.

Product Displays

You often see electromagnetic levitation modules in stores and exhibitions. They make products float in mid-air, catching your eye and making you curious. The module sits inside a base, hidden from view, and uses sensors to keep the product steady.

You can display anything from jewelry to electronics, and even art pieces. The system works for objects weighing from a few grams up to 10 kilograms. You can customize the display for single items or multiple products. The floating effect makes your product stand out and gives your store a modern, high-tech look.

When you use electromagnetic levitation modules in displays, you attract more attention and create a memorable experience for customers.

Microbotics

You find electromagnetic levitation modules in the world of microbotics, where tiny robots move and work without wires. Researchers use special coils and magnets to control the position and movement of microrobots. These robots can swim, crawl, or spin in small spaces.

Study / Research Group | Electromagnetic System Description | Application / Emerging Use | Key Performance Metrics | Limitations |

|---|---|---|---|---|

Chan Kim et al., Chonnam National University | Six electromagnetic coils (up to 671 turns), generating 1.5 T/m magnetic field gradient | Targeted manipulation of ferromagnetic fluids | Control range ~10 mm | Limited long-distance control |

Kim Tien Nguyen et al., Korean Institute of Medical Microrobots | Free-point driving systems with 4, 6, and 9 coils, max current 10 A | Tracking magnetic microparticles in living mice | Wireless control in physiological environments | Power consumption and coil complexity |

Michael P. Kummer et al., ETH Zurich | Eight orthogonal electromagnetic coils, 712 turns, 20 A current | 5 degrees of freedom microrobot motion control | Magnetic field ~15 mT, limited operational range | Limited long-distance application, high power demand |

Gilgueng Hwang et al., Laboratoire Photonique et Nanostructures | Four-coil system, 630 turns, 1 A current | Propulsion of bilayer microrobot | Small control area (4 mm x 3 mm) | Restricted to 2D movement, fixed coil positions |

Gwangjun Go et al., Johns Hopkins University | Nine electromagnetic coils, 1368 turns | 2 rotational + 3 translational DOF microrobot control | Control area diameter 120 mm | Complex coil design, scalability challenges |

You see these tiny robots used in medicine for targeted drug delivery, surgery, and diagnostics. The electromagnetic levitation module lets you control the robots without touching them, even inside the human body. You can move them in two or three dimensions, but you still face challenges with power and control range.

Microbotics with electromagnetic levitation modules opens new doors for healthcare and research.

You have seen how an electromagnetic levitation module lets you lift and move objects without touching them. This technology powers maglev trains, medical tools, and even floating displays. The market is growing fast, especially in Asia-Pacific, with new uses in 3D bioprinting and diagnostics:

Segment | Market Share (2023) | CAGR (2024–2030) |

|---|---|---|

3D Bioprinting | 45% | 12% |

Diagnostics | 30% | 10% |

Asia-Pacific | 38% | 15% |

Maglev systems lower energy use and maintenance costs.

Ongoing research makes these modules more efficient and affordable.

You may face challenges like high costs and complex controls, but new breakthroughs keep coming. Imagine what you could create if you harnessed this technology in your own projects.

FAQ

How do electromagnetic levitation modules keep objects stable?

You see sensors measure the object’s position. The control system adjusts the magnetic field quickly. This keeps the object balanced and prevents it from falling or wobbling. Fast feedback helps you maintain stability, even if something bumps the object.

Tip: Stability depends on real-time sensor feedback.

Can you use electromagnetic levitation modules at home?

You can use small modules for product displays or science experiments. Many kits let you levitate lightweight objects safely. You must follow safety instructions and avoid strong magnets near electronics or medical devices.

Use Case | Safety Level | Notes |

|---|---|---|

Product Display | High | Easy to set up |

Science Project | Medium | Adult supervision best |

What materials can you levitate with these modules?

You can levitate metals like aluminum, copper, and some alloys. Superconductors work for special applications. Most modules need objects that respond to magnetic fields. Non-metal items usually do not float unless you add a magnet inside.

Are electromagnetic levitation modules energy efficient?

You save energy because there is no friction. Maglev trains and magnetic bearings use less power than traditional systems. You still need electricity for the magnets and control circuits. Efficiency improves with better design and advanced control algorithms.

What are the main challenges when using electromagnetic levitation?

You face high costs, complex controls, and limited weight capacity. Strong magnetic fields can interfere with electronics. You must calibrate sensors and maintain the system. Research continues to solve these problems and make modules easier to use.