How Magnetic Levitation Systems Work

You see objects float above the ground in a magnetic levitation system because magnets push and pull against each other. This force lifts heavy things without touching the surface. Magnetic levitation lets trains travel much faster than regular trains. You notice less noise and smoother rides because there is no friction.

Maglev trains reach speeds over 375 mph.

You need less maintenance since there is no contact with tracks.

Safety improves because derailments happen less often.

Key Takeaways

Magnetic levitation systems allow objects to float using magnets, reducing friction and enabling faster travel.

Maglev trains can reach speeds over 375 mph, offering a smoother and quieter ride compared to traditional trains.

Safety is enhanced in maglev systems, as they have lower chances of derailments and require less maintenance.

Electromagnetic and superconducting levitation technologies provide unique benefits, such as energy efficiency and stability.

Despite higher initial costs, maglev systems promise long-term savings through reduced operational expenses and environmental impact.

Principles Of Magnetic Levitation System

You can understand how a magnetic levitation system works by looking at the science behind it. Magnetic forces create an upward push that balances the pull of gravity. This balance lets objects float without touching the ground. You see this in maglev trains, where the train hovers above the track.

Tip: Stability is important. If the floating object tips or slides, the system must quickly correct its position to keep it safely levitating.

Electromagnetic Levitation

You find electromagnetic levitation in many maglev trains. Electromagnets create strong magnetic fields. These fields push against each other and lift the train. Sensors watch the train’s position and speed all the time. The control system adjusts the electromagnets in real time. This keeps the train at a steady height above the track.

Electromagnets can switch on and off very fast.

If the train tilts, the system activates the right electromagnet to bring it back to center.

This active control keeps the train stable and safe.

You can calculate the lift force using magnetic pressure. The formula is:

P_mag = B^2 / (2μ_0)

where P_mag is the force per unit area, B is the magnetic field strength, and μ_0 is the permeability of vacuum. This shows how magnetic fields can create enough upward force to fight gravity.

Superconductor-Based Levitation

You see another type of magnetic levitation system that uses superconductors. When you cool certain materials to very low temperatures, they become superconductors. Superconductors have zero electrical resistance. They also show the Meissner effect, which means they push away magnetic fields. This effect lets a magnet float above a superconductor.

Superconductors conduct electricity without resistance at low temperatures.

The Meissner effect causes them to repel magnetic fields.

Below a certain temperature, called the critical temperature, superconductors become diamagnetic. This strong repulsion lets you levitate magnets above them.

You can use high-temperature superconductors for easier cooling. Liquid nitrogen cools these materials, making them more practical than low-temperature superconductors.

Type of Superconductor | Critical Temperature Range |

|---|---|

High-Temperature (HTS) | Above 77 K (−196.2 °C) |

Low-Temperature (LTS) | Below 30 K (−243.15 °C) |

Iron Pnictides | Varies, some below 30 K |

You can pin superconducting objects in place using external magnetic fields. This creates quantum levitation, where the object stays locked in position above the magnet.

A magnetic levitation system uses these principles to keep objects floating and stable. You see how magnetic forces and smart control systems work together to fight gravity and create smooth, contactless motion.

Main Components

Magnets And Coils

You find magnets and coils at the heart of every magnetic levitation system. Neodymium magnets play a key role because they create strong magnetic fields. Their high strength lets you lift heavy objects with less energy. These magnets also come in small sizes, so you can design compact and efficient systems. When you use neodymium magnets, you get better energy conversion and lower power use. Coils, often made of copper wire, work with magnets to generate and control the magnetic fields. You see these coils wrapped around parts of the track or train, helping to create the lift and movement needed for levitation.

Control Systems

You rely on control systems to keep the magnetic levitation system stable and safe. These systems use sensors to watch the position and speed of the levitating object. When the object moves out of place, the control system reacts fast. It uses strategies like PID controllers to adjust the magnetic force. This keeps the object floating at the right height. The system faces challenges because the forces can change quickly and are hard to predict. Engineers use special methods to make sure the system stays stable, even when conditions change. You benefit from these controls because they help prevent accidents and keep the ride smooth.

Note: Control systems often use computer simulations to test and improve their responses before real-world use.

Propulsion Mechanism

You see different propulsion mechanisms in maglev trains. Each one moves the train forward in a unique way. The table below shows the most common types and how they work:

Propulsion Mechanism | Functionality |

|---|---|

Electromagnetic Suspension Systems (EMS) | Provides both levitation and propulsion using an onboard linear motor. The stators change polarity to move the train forward, with speed controlled by the frequency of alternating current. |

Electrodynamic Suspension Systems (EDS) | Levitation is achieved using onboard magnets, while propulsion requires additional technology like linear motors in the track. The propulsion process involves a ‘pull-then-neutral-then-push’ system, utilizing repulsion to move the train. |

You notice that each propulsion system works with the magnets and control systems to create smooth, fast, and efficient movement. When you combine these main components, you get a magnetic levitation system that can lift, stabilize, and move objects without touching the ground.

Types Of Magnetic Levitation System

When you look at a magnetic levitation system, you find three main types. Each type uses different technology to make objects float and move without touching the ground.

Electromagnetic Suspension (EMS)

You see EMS in many maglev trains, especially in Germany and China. EMS uses electromagnets on the train and metal rails on the track. The magnets pull the train upward, keeping it about 1.3 centimeters above the guideway. Sensors and feedback systems watch the train’s position and adjust the magnets to keep it steady.

EMS uses attractive forces between the train and the track.

The system can keep the train floating even when it is not moving.

You get a very stable and quiet ride.

Tip: EMS needs a complex control system to keep the train balanced and safe.

Electrodynamic Suspension (EDS)

You find EDS in some high-speed trains, like those in Japan. EDS uses strong magnets on both the train and the track. These magnets push against each other, creating a repulsive force. The train floats about 10 centimeters above the track, but it must reach a certain speed before it can levitate.

Feature | Electrodynamic Suspension (EDS) | Electromagnetic Suspension (EMS) |

|---|---|---|

~10 cm | ~1.3 cm | |

Force Type | Repulsive | Attractive |

Levitation at Zero Speed | No | Yes |

Ride Stability | Self-stabilizing | Needs active control |

Speed | Very high | High |

You notice EDS trains can go faster and use less energy once they are floating. However, they need special cooling for superconducting magnets and more complex tracks.

Superconducting Maglev

Superconducting maglev trains use superconductors to create powerful magnetic fields. When you cool these materials, they lose all electrical resistance. This makes the train float higher and move with less energy. Superconducting maglev systems show better energy efficiency and stability than other types.

Metric | Superconducting Maglev | Conventional Maglev |

|---|---|---|

Energy Efficiency | Improved by 96.8% | Baseline |

Operational Stability | Enhanced | Standard |

Energy Use (per km) | Less than 20% of planes | Higher |

Cooling Cost | Reduced | Higher |

Note: Superconducting maglev trains cost more to build, but you get smoother rides and lower energy use over time.

Each type of magnetic levitation system offers unique benefits. You can choose the best one based on speed, stability, and cost.

Applications & Challenges

Real-World Uses

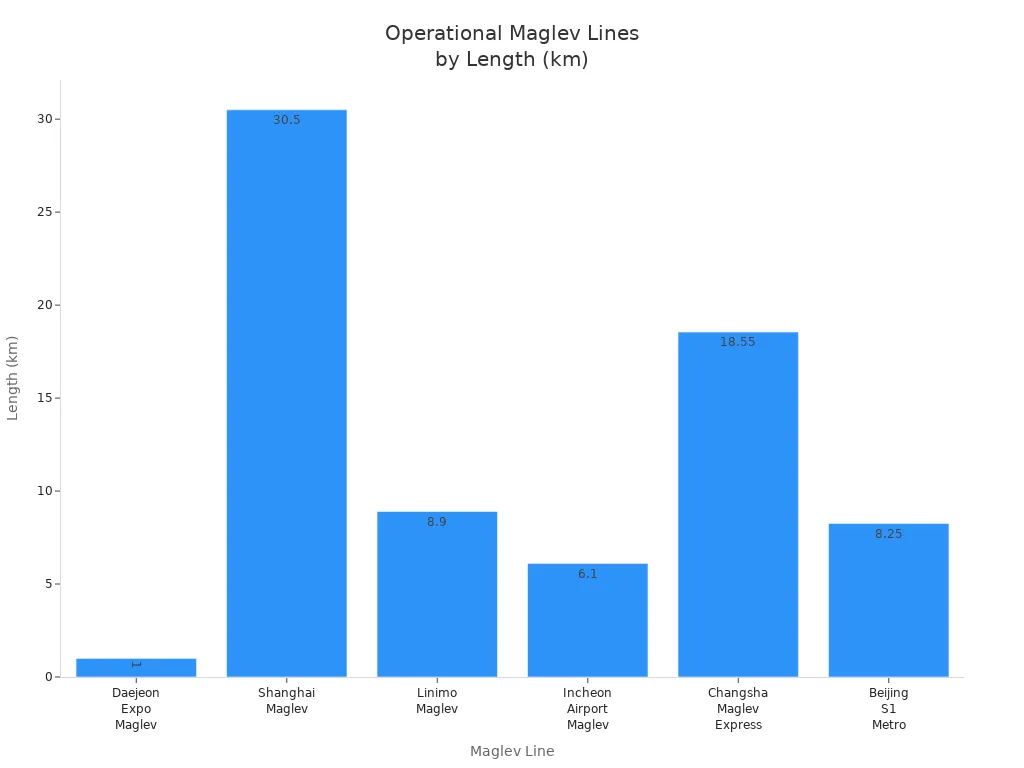

You see magnetic levitation systems in action around the world, especially in transportation. Maglev trains carry passengers at high speeds in places like China, Japan, and South Korea. These trains float above the tracks, so you experience smooth and quiet rides. You also find maglev technology in airport shuttles, industrial conveyors, and even some medical devices. The table below shows several operational maglev train lines and their lengths:

Maglev Line | Length (km) | Year Operational |

|---|---|---|

Daejeon Expo Maglev, South-Korea | 1 | 1993 |

Shanghai Maglev, China | 30.5 | 2004 |

Linimo Maglev, Japan | 8.9 | 2005 |

Incheon Airport Maglev, South-Korea | 6.1 | 2016 |

Changsha Maglev Express, China | 18.55 | 2016 |

Beijing S1 Metro Line, China | 8.25 | 2017 |

Benefits (Speed, Efficiency, Safety)

You benefit from maglev trains because they travel much faster than regular trains. For example, the Japanese Maglev reaches speeds up to 375 mph (603 km/h), while the Shanghai Maglev goes up to 270 mph (435 km/h). The table below compares maximum speeds:

Train Type | Maximum Speed (mph) | Maximum Speed (km/h) |

|---|---|---|

Japanese Maglev | 375 | 603 |

Shanghai Maglev | 270 | 435 |

South Korean Maglev | 68 | 109 |

You also notice improved energy efficiency. Maglev trains use less energy per passenger mile than airplanes and some traditional trains. They produce lower CO2 emissions, helping the environment. At high speeds, maglev trains consume only about one-fifth of the energy per passenger kilometer compared to airplanes. You see fewer accidents with maglev trains. In Japan, maglev technology has operated since the 1960s without any fatalities from crashes or derailments. This strong safety record stands out compared to conventional rail systems.

Tip: Maglev trains offer a cleaner and safer way to travel, reducing noise and air pollution.

Limitations & Technical Challenges

You face several challenges with magnetic levitation systems. Building maglev tracks costs much more than traditional railways. For example, the Tokyo-Nagoya Maglev line costs about 77 million dollars per kilometer. You need advanced control systems to keep trains stable and safe. Managing strong magnetic fields adds complexity. Regulatory standards for maglev are still developing, which slows down new projects. Maintenance requires expert knowledge and careful coordination. The table below compares infrastructure and operational costs:

Aspect | Maglev Systems | Traditional Rail Networks |

|---|---|---|

Infrastructure Costs | Generally higher due to advanced tech | Generally lower |

Operational Costs | Significantly lower due to no friction | Higher due to wear and maintenance |

Maintenance Requirements | Minimal, as there is no mechanical wear | Regular maintenance needed due to wear |

You also notice high initial energy demands for levitation and propulsion, but maglev trains become more efficient at higher speeds. Environmental concerns exist, but using renewable energy can help reduce the impact.

You see how a magnetic levitation system uses electromagnets and guidance magnets to lift trains without friction. This technology gives you faster travel, less noise, and lower maintenance. You face high costs and big investments, but strong growth is expected. The global maglev market could reach $25.5 billion by 2035.

Year | Market Size (USD Million) | CAGR |

|---|---|---|

2024 | 3,110 | N/A |

2025 | 3,770 | 21.0% |

2035 | 25,500 | N/A |

New innovations will shape the future:

High-speed rail and urban transport improvements

Efficient freight movement

Possible space launch applications

FAQ

What makes maglev trains different from regular trains?

You see maglev trains float above the tracks using magnets. Regular trains roll on wheels. Maglev trains move faster, make less noise, and need less maintenance because nothing touches the track.

How safe are magnetic levitation systems?

You get a very safe ride with maglev technology. The system uses sensors and controls to keep the train stable. Accidents rarely happen because the train cannot derail easily.

Can you use magnetic levitation for things other than trains?

You find maglev technology in airport shuttles, factory conveyors, and some medical devices. Engineers also test maglev for moving goods and even launching spacecraft in the future.

Why do maglev trains cost so much to build?

You pay more for maglev tracks because they need special magnets and advanced control systems. The technology is new, so building and maintaining it costs more than regular railways.